The machine is widely used for automatic packaging of individual or collective boxes in pharmaceutical, food, cosmetics, stationery, audio and video products, electronic hardware and other industries. Such as wrapping medicine, poker, packaged cigarettes, boxed VCD, tapes, boxed napkins, etc.

1. Anti-counterfeiting, dust-proof and moisture-proof functions.

2. Improve product grade and added value.

3. Enhance production efficiency and reduce production costs.

The machine can be combined with the front-end box-filling machine and the back-end box-filling machine to form a linkage production line.

The machine can be customized and enlarged according to customers'requirements.

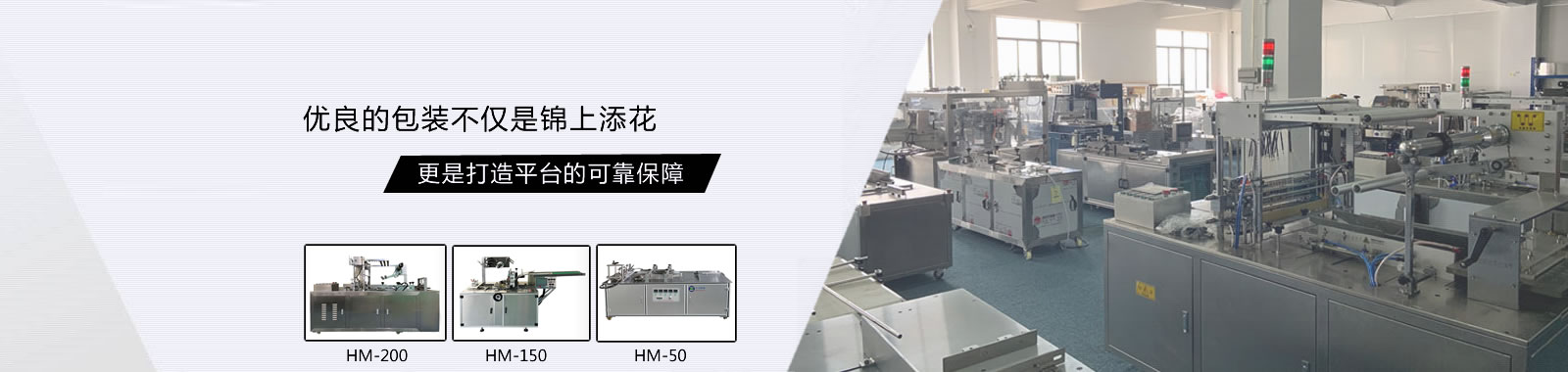

Product Description:

This machine is controlled by human-machine interface of imported PLC. Its action is driven by cylinder. The submerged membrane system is controlled by what kind of motor. It can adjust the size of submerged membrane arbitrarily. It has the characteristics of stable and reliable operation, firm sealing, smooth and beautiful, and maintenance-free. At the same time, it has the function of automatic folding boxes. The machine body is composed of stainless steel frame and enclosed plexiglass protective cover. The body platform and parts are made of stainless steel material, which meets the hygienic standards and has a beautiful appearance. It is a domestic advanced three-dimensional packaging equipment with box-type package assembly or larger items.

Product parameters:

Model HM-200A

Packing speed 30-60 boxes per minute

Packing specifications 100-300 mm long, 50-250mm wide and 15-90 mm high

Packaging materials BOPP

Packaging materials require inner hole diameter: 75mm thickness: 0.018-0.040mm

Thermal Sealing Temperature 100-150 C

Power supply 220V/380V/50HZ-60HZ

Total power 10KW

Working Pressure 0.6-0.7 MPa

Comprehensive Noise < 59dB

Shape size 2000 * 950 * 1700mm (L * W * H)

Machine weight 850 kg